Chemists in Japan, Canada and Europe have uncovered flaws in the surface structure of cellulose nanocrystals—an important step toward deconstructing cellulose to produce renewable nano-materials relevant to biochemical products, energy solutions, and biofuels. The findings – published in Science Advances – are the most detailed look yet at the surface chemistry and structure of individual cellulose nanocrystal (CNC) particles.

(A) AFM image of structural defects on CNC surface, acquired in water. (B) High-resolution AFM topography image of an individual CNC surface, revealing the details of the molecular organization at the interface. (C) The reconstructed image of the surface in panel B, obtained by executing inverse 2D-FFT spectra. (D and E) 2D vertical ∆f maps of the cellulose-water interface, indicating the structurally ordered water layers. © 2022 Yurtsever, et al.

The team, led by researchers at Kanazawa University, applied three-dimensional atomic force microscopy (3D-AFM) and molecular dynamics simulations to individual CNC fibres in water. The high-resolution scanning revealed new details of the cellulose chain arrangements on the CNCs surfaces.

“This an essential step towards understanding the mechanisms of CNC degradation, which is crucial for biomass conversion, with relevance to renewable nanomaterials and chemical production,” said Professor Takeshi Fukuma, Director of the Nano Life Science Institute at Kanazawa University.

For the most part, the structure of a single CNC fibre showed honeycomb or zigzag chain arrangements on crystalline portions, interspersed with disordered, non-crystalline regions at irregular intervals. The researchers uncovered structural defects associated with the non-crystalline regions of the surface.

“This is a great example of an international collaboration developed at the Nano Life Science Institute at Kanazawa University,” said University of British Columbia Professor Mark MacLachlan, Canada Research Chair in Supramolecular Materials and co-author on the paper. “It is important to visualize the surface and defects in these natural structures in order to advance their applications.”

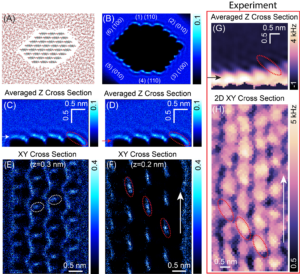

(A) A molecular dynamics snapshot of cellulose nanocrystal in water. The c-axis is perpendicular to the image plane. (B) 3D simulated water oxygen density map around a hexagonal-shaped CNC with crystalline planes labeled. (C and D) Averaged vertical 2D density map of water oxygen atoms above the (010) crystalline plane, taken through zx plane along the perpendicular direction to the chain axis. (E and F) 2D horizontal water density slices extracted from the 3D map at the vertical positions marked with white and red arrows in panel E and D, respectively. (G and H) Experimentally obtained vertical and horizontal 2D ∆f maps of the cellulose-water interface, respectively. © 2022 Yurtsever, et al.

Chemists with Professor MacLachlan’s lab at UBC helped devise the experiment, and synthesized and purified the cellulose nanocrystals for the project. Computational studies and modeling were undertaken by a team from Finland, led by Professor Adam Foster.

The study also modelled the three-dimensional arrangement of water molecules near the CNC surface—which might offer material scientists additional clues to how the CNC surface might respond to molecular adsorption, diffusion and chemical reactions.

About CNCs

Cellulose is a tough, fibrous and water-insoluble renewable biopolymer that gives living plant cells their structure. CNCs are the product of converting part of cellulose—the microfibrils—into almost perfect crystalline structures. The result is stiff rod-like particles also referred to as whiskers. Typically, sources of cellulose are converted into CNCs using chemicals or through mechanical manipulation.

CNCs have potential applications in enzyme immobilization, developing antimicrobial and medical materials, green catalysis, bio-sensing, and creating drug carriers.

3D Atomic Force Microscopy

Conventional AFM captures images of the surface of an object. Professor Takeshi Fukuma and his colleagues at Kanazawa University have developed a 3D AFM system that spatially resolves the features on the surface of an object but also at its interface with water by moving the microscope’s tip horizontally and vertically in the 3D interfacial space.

Funding

The study was funded by MEXT Japan, the Natural Sciences and Engineering Research Council of Canada, and the Academy of Finland’s Flagship Program.

Reference

Title: Molecular insights on the crystalline cellulose-water interfaces via three-dimensional atomic force microscopy; Journal: Science Advances 8, eabq0160 (2022). Authors: Ayhan Yurtsever*, Pei-Xi Wang, Fabio Priante, Ygor Morais Jaques, Keisuke Miyazawa, Mark J. MacLachlan, Adam S. Foster, Takeshi Fukuma*; DOI: 10.1126/sciadv.abq0160

Source

University of Kanazawa, press release, 2022-10-25.

Supplier

Kanazawa University

University of British Columbia

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals