Already the basis of a fledgling industry, they’re a class of polymers naturally created by living microorganisms, or synthetically produced from biorenewable feedstocks. They’re biodegradable in the ambient environment, including oceans and soil.

But there’s a reason PHAs haven’t taken off as a sustainable, environmentally benign alternative to traditional plastics. Crystalline PHAs are brittle, so not as durable and convenient as conventional plastics. They cannot easily be melt-processed and recycled, making them expensive to produce.

Colorado State University polymer chemists led by Eugene Chen, University Distinguished Professor in the Department of Chemistry, have created a synthetic PHA platform that addresses each of these problems, paving the way for a future in which PHAs can take off in the marketplace as truly sustainable plastics.

Chen and colleagues report a new class of redesigned PHAs, readily accessible via chemical catalysis, in the journal Science.

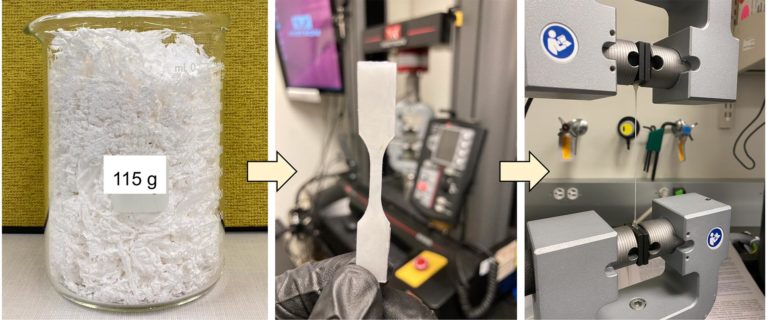

The researchers had been searching for a strategy to address the intrinsic thermal instability of conventional PHAs; their lack of heat resistance also makes it difficult to melt-process them into end products. The CSU chemists made fundamental changes to the structures of these plastics, substituting reactive hydrogen atoms responsible for thermal degradation with more robust methyl groups. This structural modification drastically enhances the PHAs’ thermal stability, resulting in plastics that can be melt-processed without decomposition.

What’s more, these newly designed PHAs are mechanically tough, even outperforming the two most common commodity plastics: high-density polyethylene – used in products like milk and shampoo bottles – and isotactic propylene, which is used to make automotive parts and synthetic fibers. The best part is that the new PHA can be chemically recycled back to its building-block molecule, called a monomer, with a simple catalyst and heat, and the recovered clean monomer can be reused to reproduce the same PHA again – in principle, infinitely.

“We are adding three key desired features to the biological PHAs, including closed-loop chemical recycling, which is essential for achieving a circular PHA economy,” Chen said.

The work was supported by the Department of Energy’s BOTTLE Consortium.

Author

Anne Manning

Source

Colorado State University, 2023-04-11.

Supplier

BOTTLE Consortium

Colorado State University

Science Magazine

US Department of Energy (DoE)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals