- Complete replacement of existing petrochemical-based solvents with environmentally friendly solvents

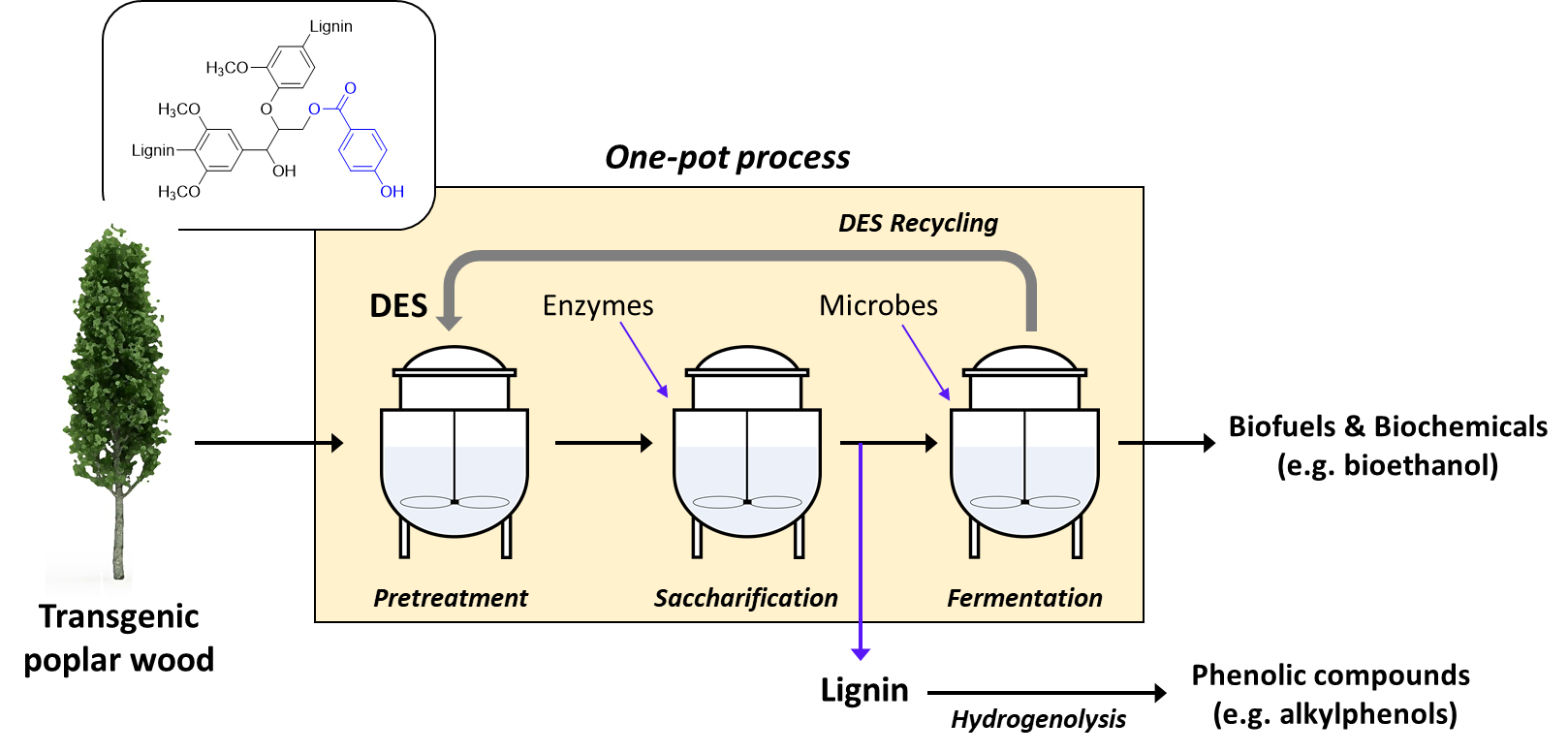

- Production of economically secured and environmentally friendly biofuels and renewable chemicals in a ‘one-pot process’

Biomass refers to biological organisms, including plants, that synthesize organic matter utilizing solar energy and animals that use these plants as food. Biomass also includes resources that can be converted into chemical energy. To achieve carbon neutrality by 2050, substantial efforts have been made worldwide to develop biorefinery technology that can replace fossil fuels with biofuels. However, the conventional biofuel production process involves the use of highly toxic solvents, which are mainly derived from petroleum causing environmental and economic concerns.

Dr. Kwang Ho Kim’s research team at the Clean Energy Research Center of Korea Institute of Science and Technology (KIST, President Seok Jin Yoon) developed a green solvent that can completely replace conventional petrochemical-based solvents while maximizing the efficiency of biofuel production. The researchers announced that it is now possible to produce sustainable and economically secured biofuels.

After screening various solvent candidates, the KIST research team synthesized a green deep eutectic solvent that is also biocompatible with microorganisms during the fermentation process. The synthesized eutectic solvents were systematically analyzed by advanced nuclear magnetic resonance spectroscopy and computational analysis. The ‘one-pot process’ based on the newly developed solvent maximized the production efficiency of high-purity biofuels and biochemicals by integrating three to four complex existing processes into one consolidated process. It was also announced that the one-pot process that uses environmentally friendly solvents is sustainable, does not emit pollutants, does not require washing water, and allows for the reuse of solvents.

Dr. Kim of KIST said, “By overcoming the uneconomical problems currently being faced by the biorefinery industry via the development of green solvents and maximization of biofuel production process efficiency, Korea will be able to take the lead in the ‘Race to Zero’ by developing this sustainable technology.”

This research was supported by by the KIST and the National Research Foundation of Korea (Minister Jong Ho Lee). This collaborative research was conducted between the University of British Columbia, State University of New York, National Institute of Forest Science of Korea and Korea Military Academy. The research results were published in the latest issue of Green Chemistry (Impact Factor: 11.034), an international journal in the energy and environment field and were selected as the back cover.

Reference

Title: One-pot conversion of engineered poplar into biochemicals and biofuels using biocompatible deep eutectic solvents; Journal: Green Chemistry; DOI: https://doi.org/10.1039/D2GC02774G

Source

KIST, press release, 2023-02-10.

Supplier

Korea Institute of Science and Technology (KIST)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals