© Emma Landis/ Pixabay

Bioplastics are conquering new areas of application, from construction to automotive industry. They help to minimize dependencies on oil and gas as well as the carbon footprint. And they are also becoming interesting alternatives in terms of price. The winners of this year’s BIOPOLYMER Innovation Awards, nominated by the jury, provide impressive evidence of those trends. During the award ceremony at the “BIOPOLYMER – Processing & Molding” congress on June 14, the winners from Belgium, Brazil and Germany will exclusively present their innovations. Participants from all over the world can take part free of charge.

The abundance of high-quality applications from Belgium, Brazil, Holland, Italy and Germany was an exciting and demanding task for the jury of the BIOPOLYMER Innovation Awards this year again. After a multi-stage selection process, the jury nominated the following three companies as candidates for the main prize endowed with 2,000 euros (listed below in reverse alphabetical order of the company names).

During the award ceremony at the “BIOPOLYMER – Processing & Moulding” congress on June 14, the hand-made trophies will be presented to the victor, to the second and third placed applicants. The three winners will present their innovations and also be available to answer questions from the audience.

Bioplastics are conquering new areas of application, from construction to automotive industry. They help to minimize dependencies on oil and gas as well as the carbon footprint. And they are also becoming interesting alternatives in terms of price. The winners of this year’s BIOPOLYMER Innovation Awards, nominated by the jury, provide impressive evidence of those trends. During the award ceremony at the “BIOPOLYMER – Processing & Molding” congress on June 14, the winners from Belgium, Brazil and Germany will exclusively present their innovations. Participants from all over the world can take part free of charge.

The abundance of high-quality applications from Belgium, Brazil, Holland, Italy and Germany was an exciting and demanding task for the jury of the BIOPOLYMER Innovation Awards this year again. After a multi-stage selection process, the jury nominated the following three companies as candidates for the main prize endowed with 2,000 euros (listed below in reverse alphabetical order of the company names).

During the award ceremony at the “BIOPOLYMER – Processing & Moulding” congress on June 14, the hand-made trophies will be presented to the victor, to the second and third placed applicants. The three winners will present their innovations and also be available to answer questions from the audience.

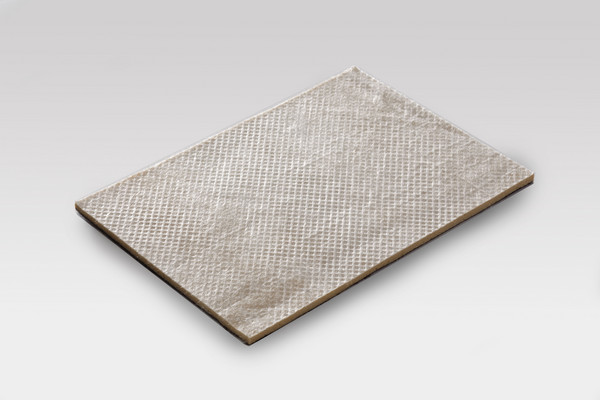

SachsenLeinen GmbH – Markkleeberg (Germany)

developed a process for manufacturing unidirectional (UD) tapes from flax and hemp fibers and bio-based plastics like PLA or PA. UD tapes are incorporated into molded parts (e.g. of microcars, sports devices) to enable highly stable and resource-saving structures combined with effective vibration damping. The fibers, which are oriented in one direction, make it possible to “dose” stiffness and strength precisely in such components with minimal weight. The natural fiber reinforced UD tapes from SachsenLeinen can not only replace the usual glass fiber reinforced UD tapes made of polypropylene or other conventional plastics, but also also set new price standards for natural fiber composite semi-finished products. The flax and hemp fibers grow in the region, the tapes can be recycled, thus reused as short fiber reinforced plastic. And depending on the used polymer they are biodegradable at the end of their lifespan.

Home Eos SA – Farciennes (Belgium

has developed a new type of biobased, biodegradable plastic: “stopsound” absorbs vibrations excellently, is naturally fire-retardant and heat-insulating. Its production requires up to eight times less energy than similar conventional plastics. The sound absorbing foam, which remains permanently elastic without plasticizers, solvents and classified chemicals, can be easily bonded to other materials. The material is used in vehicle construction as well as, for example, in floors, facades or in industrial noise protection. With the extensively certified bioplastic, classic petrochemical materials such as bitumen, PVC or EPDM can be replaced on a large scale in the future.

Earth Renewable Technology (ERT) – Curitiba, Brazil

convinced the jury with a masterpiece in compounding technology which opens up new application possibilities for the world’s most widely used biopolymer, polylactide (PLA). With its “Short Fiber Reinforced (SFRP) in FC 10130 biopolymer composite”, the US company, which has been active in Brazil since 2021, integrated PLA fibers into a PLA matrix. The resulting mono-material is not only extremely easy to recycle, but also gives significantly improved usage properties to PLA. According to ERT data, the elongation increases up to fifty times. Impact strength is quintupled and the heat deflection temperature doubled. The barrier effect against water vapor increases up to twentyfold, that against oxygen up to fourfold. The technology can be used in injection molding, extrusion processes and thermoforming.

© Earth Renewable Technologies

Author

Frank Pollack

Source

Polykum, press release, 2022-06-03.

Supplier

Earth Renewable Technologies Biocompounds

Eos Technology

Polykum e.V.

SachsenLeinen GmbH

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals