Avantium N.V., a leading company in renewable and circular polymer materials, will provide an update on its progress, strategy and plans during a Capital Markets Day it will hold for institutional investors today at 10:00 hrs CET and for retail investors today at 15:00 hrs CET.

Avantium is reaching the inflection point

- The Company is fully focused on launching commercial operations at its FDCA Flagship Plant:

-The time schedule for the project remains in line with previous guidance, with commissioning activities expected to commence in the first quarter of 2024 and FDCA production in the second half of 2024;

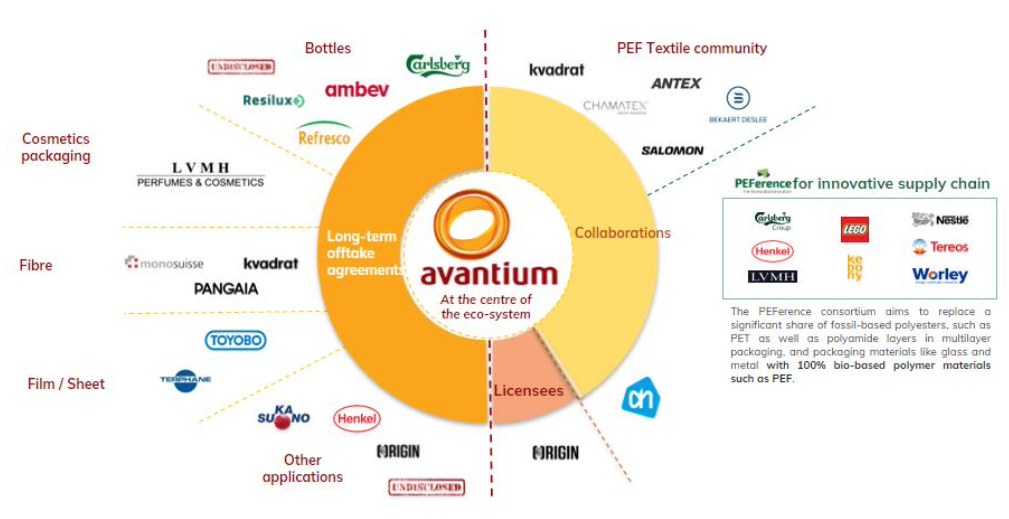

-To date, Avantium has signed 15 commercial offtakes agreements for FDCA and PEF from the FDCA Flagship Plant, for a diverse range of applications;

- The FDCA Flagship Plant serves as a stepping stone in Avantium’s licensing strategy:

-Avantium has already entered into its first licensing agreement with Origin Materials and the Company has developed a pipeline of potential licensing partners;

-To enable the rapid deployment of FDCA and PEF in line with the demands of the market, Avantium aims to sell multiple technology licenses;

- Assuming the successful start-up of the FDCA Flagship Plant in 2024 and the sale of multiple technology licenses, management’s ambition is that the Company could generate €100 million in revenuesi and be EBITDA positive in 2026.

Avantium is reinforcing its strategic focus

- The Company is prioritising the commercialisation of its FDCA and PEF technology and the acceleration of its licensing strategy:

– Avantium will focus its resources on the start of FDCA production in the second half of 2024 and the acceleration of its licensing business, to fully benefit from the commercial opportunity for PEF market adoption which is showing strong momentum;

- As a result, further investments in the Ray TechnologyTM to produce the plant-based glycols, plantMEG and plantMPG, have been put on hold until appropriate strategic equity partners have been secured:

– The Company will reallocate some of its Ray TechnologyTM employees to the FDCA Flagship Plant project in Delfzijl, allowing the FDCA Flagship Plant to be immediately fully staffed. The decision to halt investments in the Ray TechnologyTM will regrettably result in workforce reductions in Avantium’s organisation in Amsterdam.

Securing additional financing for the FDCA Flagship Plant

- The total expected costs for Avantium Renewable Polymers, including the construction of the FDCA Flagship Plant, are now estimated to amount to approximately €255 million by the end of 2024, an increase of approximately €63 million compared to the initial forecast of €192 million; these cost increases have been primarily driven by inflation, interest rates and supply chain disruption being experienced by EPC construction projects all around the world;

- Avantium Renewable Polymers, which is the entity responsible for the FDCA Flagship Plant, has successfully received commitments for a €64.5 million financing package from its shareholders (BioPlastics Investment Groningen (BPIG) consortium, Worley and Avantium N.V.) and from its lenders, to cover the anticipated cost increases until the FDCA Flagship Plant is operational.

- In order to cover its share in the financing package for Avantium Renewable Polymers and to remain properly capitalised until the FDCA Flagship Plant is fully operational, Avantium intends to raise €50 million in equity capital.

Tom van Aken, CEO of Avantium, comments: “Over the past two years, Avantium has undergone a remarkable transition, evolving from a company primarily focused on R&D to one at the cusp of having large- scale manufacturing and commercialisation capabilities. The construction of our FDCA Flagship Plant is nearing completion and we are fully focused on reaching the pivotal milestone of starting production in the second half of 2024. We expect this to unlock our licensing strategy going forward and to support our ambition to become a €100 million revenue & EBITDA positive company in 2026.

“To reinforce our strategic focus on the commercialisation of FDCA and PEF, we have decided to put further investments in our Ray TechnologyTM on hold until strategic equity partners have been secured. This was not an easy decision, since this means that we will also part ways with some of our talented employees. We deeply appreciate their contributions to Avantium and will do our best to support them in their future endeavors.”

“We are very pleased that we have secured an additional financing package for our FDCA Flagship Plant and highly value the support from our strategic partners and lenders. Through this secured financing package, together with a successful equity raise, we expect to remain well capitalised until our FDCA Flagship Plant is fully commercially operational. We are on the verge of a significant inflection point for Avantium. We look forward to bringing our exciting, innovative product PEF to a wide range of large end-markets around the world, thereby creating substantial value for our shareholders.”

Progress, strategy and capital plan

Avantium Renewable Polymers is on track to produce commercial quantities of FDCA from its own Flagship Plant, thereby unlocking multiple additional licensing opportunities for its FDCA technology. These new licenses a recentral to Avantium’s business plan.

The construction of the FDCA Flagship Plant in Delfzijl, the Netherlands, continues to progress in line with the goal of starting FDCA production in the second half of 2024. Avantium plans to commission the FDCA Flagship Plant in phases, starting in Q1 2024, followed by the sequential start-up of the different sub-units of the Flagship Plant. A video demonstrating the progress on the FDCA Flagship Plant is to be found on the Avantium website or on YouTube.

To date, Avantium has signed 15 commercial offtake agreements with major brand names worldwide for a range of applications, including (i) bottles and packaging (food and cosmetics), (ii) fibres for interior textiles, fashion & industrial applications, and (iii) adhesives. Offtake partners include Carlsberg (beer packaging), LVMH (cosmetics packaging), AmBev (bottles), Kvadrat (interior textiles), PANGAIA (apparel) and Refresco (bottles).

Avantium is also collaborating with the largest supermarket chain in the Netherlands, Albert Heijn, to enable them to use Avantium’s 100% plant-based PEF for the packaging of Albert Heijn’s own-brand products. Albert Heijn is the first supermarket chain in the world to plan to introduce PEF packaging. Once the FDCA Flagship Plant is operational, Refresco (a global independent beverage solutions provider) intends to produce Albert Heijn’s new fruit juice bottle from PEF. This will be the first PEF application to be introduced in Albert Heijn stores. With partners like Albert Heijn and the 15 committed offtakers mentioned previously, Avantium will be able to further scale-up and expand its PEF value chain to meet the growing global consumer demand for circular and renewable material solutions.

The FDCA Flagship Plant will serve as a stepping stone for Avantium’s licensing strategy. Avantium will sell FDCA and PEF directly from its FDCA Flagship Plant to its customers, in parallel to the ultimate goal to sell technology licenses to industrial partners. As part of its licensing strategy, Avantium focuses on three main types of companies: (i) feedstock suppliers, who process agricultural raw materials, such as corn, wheat, sugar cane and sugar beet, to produce starch and sugar, (ii) chemical companies, who manufacture base chemicals and monomers for the production of plastics, and (iii) PET/polymer producers. Avantium has already entered into its first licensing agreement with Origin Materials for the conversion of CMF derivatives produced by Origin Materials into FDCA at a proposed 100 kilotonnes per annum scale facility. Under this licensing agreement, Avantium is eligible to receive upfront milestone payments and royalties for each metric tonne of FDCA produced at the licensed plant.

Running a fully operational FDCA Flagship Plant and selling multiple licenses will lead to Avantium reaching a key inflection point. Under such conditions, management’s ambition is that Avantium could generate €100 million revenue and be EBITDA positive in 2026. Our licensing assumption is that by 2026 we would capture ~6.5% of the total addressable market of 100 kilotonnes licensed FDCA plants, which is estimated at 7.7 million tonnes per yearii (i.e. 77 licensed plants of 100 kilotonnes per year). Our assumption is that these new licensing agreements would have a commercial structure similar to the license agreement with Origin Materials. In the longer term, once FDCA is produced at industrial scale and PEF is anticipated to be competitive with PET, we expect to further benefit from a growing addressable market, estimated at 122 million tonnes per yeariii.

Strategic focus on the FDCA and PEF commercial opportunity

Avantium’s major priority going forward is the commercialisation of the FDCA and PEF technology and the acceleration of its licensing strategy, representingthe most promising high-growth and high-margin opportunities in the near term as evidenced by the commercial momentum that Avantium experienced over the last few months. Over the past years, Avantium has developed the Ray TechnologyTM for the production of plantMEG and plantMPG. The current development stage of the Ray TechnologyTM would allow Avantium to advance towards the engineering of a Flagship Plant for Ray TechnologyTM.

Avantium would, however, need to invest significantly – both financially and in human resources – in the design, engineering and construction of such a plant. Avantium has now decided to prioritise the commercialisation and licensing of FDCA and PEF and will therefore put further investments in its Ray TechnologyTM on hold until one or more appropriate strategic equity partners with sufficient financial resources have been secured. Cosun Beet Company will focus on its role of strategic feedstock supplier, and it is no longer foreseen that they will become a substantial shareholder in a Ray Flagship Plant. Avantium will significantly scale down the Ray TechnologyTM team, and a smaller, dedicated team will continue to pursue potential strategic equity partners for the further development of Ray TechnologyTM towards a Flagship Plant. Such parties could jointly contribute their expertise, (manufacturing) capacities and make capital commitments, strengthening the full value chain in the Ray Flagship Plant project.

Avantium continues to advance its Volta Technology, which uses electrochemistry to convert CO2 into high- value chemical building blocks and sustainable plastic materials, including the very promising polymer material PLGA. Through the successful sourcing of grants, Volta Technology has required limited funding from Avantium. In 2023, Volta Technology successfully entered into agreements with SCGC and Norsk Hydro, with the intention of continuing the development of Volta Technology with their (financial) support. In 2024, the Company intends to continue development of this technology and scale-up in the next two years to a pilot plant with an indicative capacity of 10 tonnes per annum, provided that it can secure strategic or financial partnerships to fund this next phase of development.

Avantium R&D Solutions is the revenue/cash generating arm of Avantium. Avantium R&D Solutions offers advanced catalyst R&D systems and services to customers worldwide. In 2022, Avantium R&D Solutions announced a revised strategy to target sustainable chemistry opportunities in four emerging markets: green hydrogen, chemical plastics recycling, adsorption and sustainable chemistry. Avantium will continue to run Avantium R&D Solutions as a stand-alone unit with its own leadership team. whilst continuing to look for strategic opportunities to grow the business.

Financing package for Avantium Renewable Polymers

Since the start of construction of the FDCA Flagship Plant in April 2022, a first-of-a-kind commercial facility, the project has been subjected to exceptionally challenging external circumstances, including high inflation, scarcity of materials and contractors, and supply chain constraints. Avantium continuously monitors the impact of these circumstances on the project and has recently finalised a thorough risk analysis together with its engineering partner Worley. This analysis has resulted in an updated budget, capital plan, and commissioning and start-up plan for the project. The total expected costs for the Renewable Polymers business unit, including the construction of the FDCA Flagship Plant, are now estimated to amount to approximately €255 million, which increase is primarily due to inflation and higher interest rates. The increased CAPEX requirement for the FDCA Flagship Plant is now estimated at €33 million, bringing the total CAPEX to €149 million (€159 million before the risk-sharing mechanism with Worley).

Based on third-party benchmarking, these increases are in line with the average cost increases observed in other comparable international EPC projects currently under construction. In support of achieving commercial operations of the FDCA Flagship Plant and the roll-out of its licensing strategy, Avantium Renewable Polymers requires an additional €12 million for working capital, commissioning, and start-up activities and operational costs, bringing the total OPEX to €83 million by the end of 2024. Interest costs have increased to €23 million (from €12 million).

The estimated total cost increase will be covered by an additional financing package of €64.5 million, comprising: (i) subordinated shareholder loans of €2.5 million by the BPIG consortium, €4.2 million by Worley and €42.9 million by Avantium N.V., and (ii) a €15 million increase of the debt facility by ABN AMRO Bank, ASN Bank, ING Bank and Rabobank, as well as Invest-NL, adding to the existing €90 million debt facility package (fully drawn by Q3 2023). This debt facility increase is subject to certain terms and conditionsiv.

Following this additional financing by the three shareholders in Avantium Renewable Polymers (Avantium, BPIG consortium and Worley), the shareholder structure of Avantium Renewable Polymers remains unchanged, with Avantium still holding 77.4% equity in its subsidiary.

Extraordinary General Meeting

Avantium intends to raise €50 million in equity capital, which is expected to cover Avantium’s funding requirement related to the financing package for Avantium Renewable Polymers and to remain properly capitalised until the FDCA Flagship Plant is operating at its full capacity. This could be increased by up to €20million, allowing Avantium to further strengthen its financial profile. The Company is in advanced discussions with several parties on pre-commitments for this equity raise. Avantium has appointed ABN AMRO Bank N.V. and Bryan, Garnier & Co as joint global coordinators to lead this equity raise and other advisors may be appointed in due time. To seek shareholders’ approval for the equity raise, Avantium is calling an Extraordinary General Meeting of Shareholders (EGM), to be held on 24 January 2024. The meeting documents, consisting of the EGM agenda and the explanatory notes, are available on the Avantium website: https://www.avantium.com/corporate-governance/#shareholders-meeting

About Avantium

Avantium is a pioneering commercial-stage company focused on renewable & circular polymer materials. Avantium develops and commercialises innovative technologies for the production of materials based on sustainable carbon feedstocks, i.e. carbon from biomass or carbon from the air (CO2). The most advanced technology is the YXY® Technology that catalytically converts plant-based sugars into FDCA (furandicarboxylic acid), the key building block for the sustainable plastic PEF (polyethylene furanoate). Avantium has successfully demonstrated the YXY® Technology at its pilot plant in Geleen, the Netherlands, and is currently constructing of the world’s first commercial plant for FDCA, with large-scale production of PEF expected in 2024. Avantium also provides R&D solutions in the field of sustainable chemistry and is the leading provider of advanced catalyst testing technology and services to accelerate catalyst R&D. Avantium works in partnership with like-minded companies around the globe to create revolutionary renewable chemistry solutions from invention to commercial scale.

Avantium’s shares are listed on Euronext Amsterdam and Euronext Brussels (symbol: AVTX). Avantium is incorporated in the Euronext Amsterdam SmallCap Index (AScX). Its offices and headquarters are in Amsterdam, the Netherlands.

i Revenue based on contractual income, not considering the possible impact of IFRS 15

ii Sources: Smithers, The future of high barrier packaging films to 2024, 2021; Smithers, The future of global flexible packaging to 2026, 2021; Smithers, The future of rigid plastic packaging to 2026, 2021; Thermoformed Packaging Market to 2025, 2018 ; PCI Wood Mackenzie, Abstract report global Multilayer PET bottles industry to 2024, 2016 ; Allied Market Research

iii Sources: Smithers, The future of high barrier packaging films to 2024, 2021; Smithers, The future of global flexible packaging to 2026, 2021; Smithers, The future of rigid plastic packaging to 2026, 2021; Thermoformed Packaging Market to 2025, 2018 ; PCI Wood Mackenzie, Abstract report global Multilayer PET bottles industry to 2024, 2016 ; Allied Market Research

iv Please read the agenda and explanatory notes of the Extraordinary General Meeting on 24 January 2024

This press release by Avantium N.V. contains information that qualified or may have qualified as inside information for the purposes of Article 7 of the Market Abuse Regulation (EU) 596/2014 (MAR).

Source

Avantium, press release, 2023-12-13.

Supplier

Albert Heijn

Ambev

Avantium Technologies B.V.

Carlsberg Group

Kvadrat

LVMH Group

Norsk Hydro

Origin Materials

Pangaia

Refresco

Worley

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals