These monomers enable Arkema to start offering certified bio-attributed specialty acrylic additives and resins for a wide range of applications. This positions the Group as a global leader in the offer of bio-attributed acrylic materials and as a key partner for customers on the market.

The launch of Arkema’s new range** of bio-attributed acrylic monomers and specialty acrylic additives and resins, mass-balance certified under the International Sustainability and Carbon Certification-PLUS (ISCC+) framework, is a key milestone in the transition to a more renewable and lower carbon economy. The replacement of fossil feedstock by bio/bio-circular feedstock will support Arkema’s customers in achieving their climate plan goals by reducing their scope 3 greenhouse gas emissions.

“The development of these bio-attributed acrylic materials is an important step on the sustainable development roadmap of Arkema and its Coating Solutions segment,” said Hervé Castres Saint Martin, Global Group President Acrylic Monomers. “These innovative products deliver the same high quality and performance that our customers expect from us, while at the same time enabling them to lower their own carbon footprint.”

Complementing Arkema’s leading segregated bio-based offer

Arkema’s use of the mass balance approach in the manufacture of bio-attributed solutions complements the bio-based segregated polymers, resins and additives Arkema is already offering. These performance bio-based segregated solutions are, to name a few:

Rilsan® and Pebax® Rnew® polyamide 11 advanced polymers, Sartomer® Sarbio UV-curing resins, Synaqua® alkyd emulsions, Crayvallac® and Coapur® rheology additives.

“Engaging in both complementary approaches of mass balance and physical segregation accelerates our innovation in renewable materials for our customers and partners, to help them achieve their own sustainable development targets,” said Richard Jenkins, Senior Vice President, Arkema Coating Solutions. “In line with Arkema’s newly reinforced commitment to the Paris Agreement, we are working diligently to reduce our environmental footprint while developing innovative materials for a more sustainable world.”

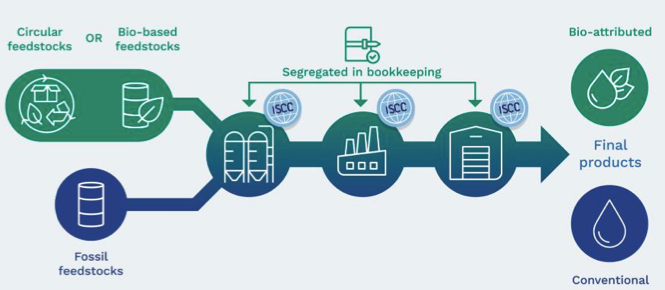

* Mass Balance : Mass balance chain of custody is designed to track the total amount of the content in scope through the production system and ensure an appropriate allocation of this content to the finished goods based on auditable bookkeeping. Property conservation principle is set to ensure that the total certified output does not exceed its original input and take into account the appropriate conversion losses and production / assembly ratios.

**Arkema plants newly certified are Carling (FR) for acrylic monomers, Genay (FR) for specialty acrylic additives and Zwickau (GE) for specialty acrylic resins. In further development phases, the production of certified bio- attributed acrylic materials will extend in Europe and other regions. This dynamic promises great potential for customers and partners to develop next-generation sustainable market solutions with Arkema.

Source

Arkema, press release, 2022-11-21.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals