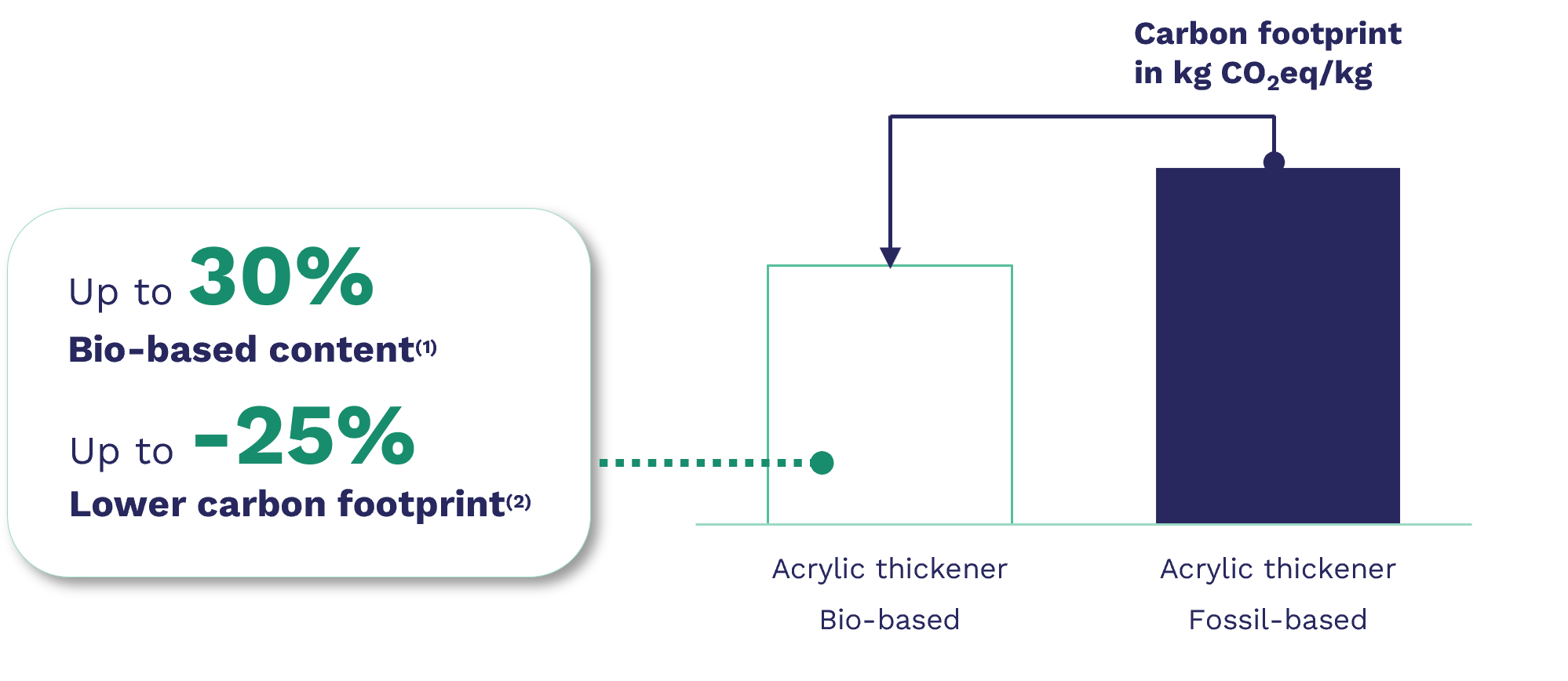

Arkema, a leader in specialty materials, converts its full line of acrylic thickeners produced in Europe, ensuring the same high performances. This initiative leads to introduce up to 30% bio-based content(1) and up to 25% product carbon footprint reduction(2) compared to standard grades(3).

.png)

“These bio-based specialty additives set the stage for the next generation of sustainable coatings & adhesives products, supporting our customers to achieve their sustainability and carbon footprint reduction goal. Developing more sustainable solutions for homes is essential to meet market expectations and establish new well-being standards.”- Helene PERNOT – Global Sustainability Marketing Director @Coating Solutions.

“Used in architectural paints, industrial coatings, plasters, renders, adhesives, sealants, and various applications to optimize the rheology of those systems, those bio-based acrylic thickeners are identical in term of performance and cost for our customers. This evolution reflects our commitment to more sustainability across the value chain.” – Yohann TRANG – Global Market Director – Construction Materials @Coating Solutions.

These bio-based acrylic thickeners will be sold under Rheotech™, Thixol™ and Viscoatex™ brands. They are the first products made with the recently announced bio-sourced ethyl acrylate produced at the Arkema acrylic monomer facility in Carling France.

Rheotech™, Thixol™ and Viscoatex™ are registered trademarks of Coatex.

(1) A bio-based product is wholly or partly derived from biomass. The biobased content is the % breakdown based on a carbon ratio following EN16640. Bio-based products here come mainly from beetroot and sugarcane.

(2) PCF cradle-to-gate including biogenic uptake according to ISO 14040, 14044 and 14067, calculated vs fossil equivalent.

Source

Arkema, press release, 2025-04-10.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals