Each year, the Advanced Recycling Conference (ARC) unites the leading minds and innovators dedicated to transforming the recycling industry for a sustainable, circular future. Taking place on 19–20 November in Cologne, Germany, and online, the Advanced Recycling Conference continues this tradition by presenting a diverse lineup of experts who showcase breakthrough technologies and pioneering solutions across advanced recycling sectors.

Among these experts is Thomas Blocher, Business Manager for Chemical Recycling at BUSS ChemTech AG, who will share insights into BUSS ChemTech’s groundbreaking PyroFilm Reactor technology, which addresses the complex challenges of recycling mixed plastic waste with precision and sustainability. In this interview Thomas provides a deep dive into how advanced chemical recycling technologies drive the circular economy in a sustainable way.

Join leading voices in advanced recycling by registering now at https://advanced-recycling.eu/registration/ and secure your opportunity to participate in this pivotal event.

1. Innovation & Sustainability

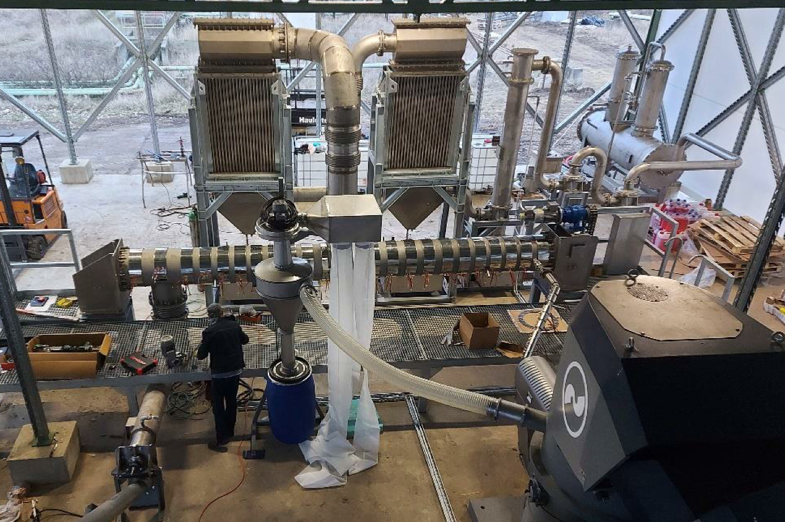

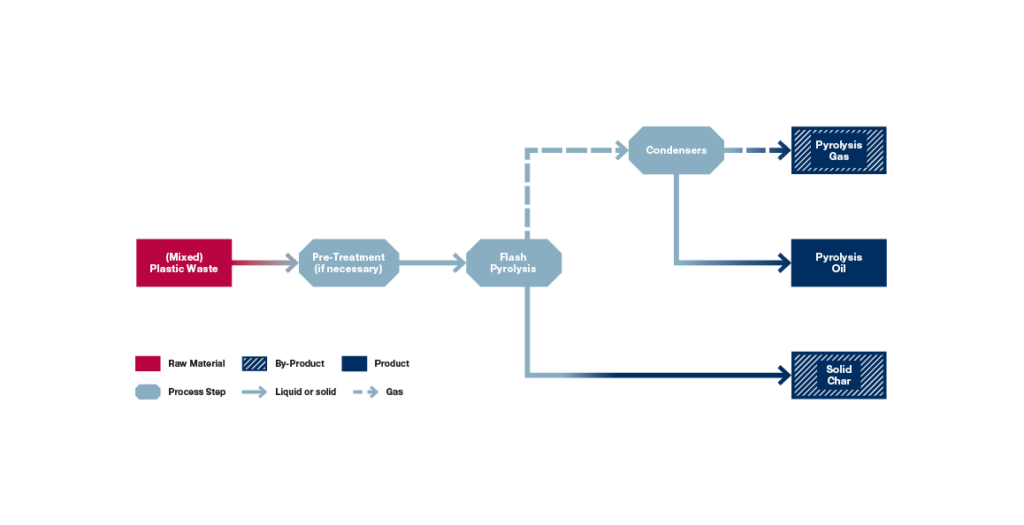

Chemical recycling is a vital technology for processing mixed plastic waste streams which traditional recycling struggles to manage. BUSS ChemTech’s patented PyroFilm Reactor uses precise heat transfer to convert such waste efficiently while minimising energy use and by-products.

Could you explain how BUSS ChemTech’s PyroFilm technology overcomes the difficulties of recycling mixed plastic waste? How does this innovation add sustainable value to your business partners, specific industry sectors and the broader advanced recycling industry?

Thomas Blocher: The main challenge in a pyrolysis reactor process is to deliver the required amount of heat to the molten polymer quickly and uniformly. There are several pyrolysis reactor types, but most of them all have the same particular challenge: mass transfer. Whether the plastic is pushed along the heat transfer surface as in a screw- or rotary kiln reactor, or an agitator promotes good mixing between the plastic and the heat transfer fluid directly, these systems are mass-transfer limited. This results in longer residence times (lower throughput) or lower quality pyrolysis oil (lower selling price). We take the novel approach of applying thin-film technology to pyrolysis. Since we are applying the heat to a minimal defined volume of molten polymer, there is virtually no mass transfer limitation. Thus, the heat is transferred evenly and very rapidly. This results in higher quality oil with lower CAPEX and OPEX.

2. Sustainability Gains Through Breakthrough Technology

Effective chemical recycling requires optimised heat transfer and integrated systems to produce consistent, high-quality pyrolysis oils, while managing energy consumption and emissions. BUSS ChemTech’s process is engineered for these goals, with equipment for solids separation and energy recovery, balancing operational reliability with product quality.

What are the main sustainability advantages of BUSS ChemTech’s process? How do these sustainability gains help recyclers, product manufacturers, and regulators achieve their environmental targets and circularity commitments?

Thomas Blocher: Another key feature of our technology is the continuous removal of the solids with no requirement of periodic shutdowns for cleaning purposes. This allows for truly continuous operations (with only an annual maintenance shutdown to check and replace wear parts, if necessary). This eliminates frequent startups minimizing wear and tear on the equipment as well as minimizing utility consumption. In our process, solids and halide-free non-compressible gas is produced which can be used directly in an engine which produces the electricity needed to power the pyrolysis unit. This minimizes or even eliminates the need to draw power from the grid. And contrary to popular belief in some quarters, pyrolysis – when done correctly – is not a “source of toxic waste”. Dangerous substances come from the waste plastic stream itself and any that remain in the output of our process, are regulated substances and are handled accordingly.

3. Challenges & Opportunities

Contaminated mixed plastics impose huge operational challenges. Feedstock heterogeneity, difficult impurities removal, and maintaining product quality result in low-recycling quotas. BUSS ChemTech’s operational experience includes the development of robust process controls and patented separation methods, addressing these issues.

What are the key practical challenges BUSS ChemTech has faced with these waste streams? How have you turned these challenges into opportunities to improve process resilience, yield, and material circularity?

Thomas Blocher: Feedstock variability is a feature of the industry. Furthermore, ongoing materials and product development – as well as changes in human behaviour – will change the composition of today’s plastic waste streams. So, even the variability is unpredictable! Any pyrolysis technology must take this into account. One way we “build in” process flexibility is through the design of the process control. The temperature profile, as well as the residence time of the plastic in the reactor, can be adjusted for different feedstock compositions or even to adjust product characteristics depending on the off-taker’s needs. And as analytical techniques improve, and operational experience is accumulated, we are moving towards virtual real-time process parameter adjustments to maximize product uniformity.

4. Collaboration & Industry Dynamic

Scaling chemical recycling technologies requires strong collaboration among technology providers, waste management companies, regulators, and brand owners, especially with evolving regulatory frameworks such as the EU’s Packaging and Packaging Waste Regulation (PPWR). Despite its potential, chemical recycling has faced criticism and challenges regarding its environmental footprint, costs, and operational viability, which have affected its reputation in the industry and public perception.

Could you share how BUSS ChemTech builds and sustains collaborative partnerships to support technology adoption and regulatory compliance? Additionally, how does your company address the negative perceptions surrounding chemical recycling, and what strategies do you believe are essential to improving its reputation and accelerating broader acceptance within the recycling community?

Thomas Blocher: Most chemical recycling technology providers are SMEs or start-ups and alone, cannot effectively get their views heard. We are fortunate to have an active industry association, Chemical Recycling Europe, that facilitates discussions between the various stakeholders, as well as to aggregate our voices into a uniform message to the regulators. Chemical recycling’s less than stellar reputation results not just from mis- and dis-information, but more from our past mistakes, which I loosely describe as “overpromising and underdelivering”. To correct this, we need to make our case with facts – countering with sourced-based information, make the case with integrity – highlighting the limitations of our technologies and not just the advantages, and make the case with transparency – providing real and not idealized performance data.

5. Future Innovations

As chemical recycling matures, innovations such as feedstock flexibility enhancements, advanced product fractionation, and digitalised plant monitoring will be critical. BUSS ChemTech continues to invest in these areas to increase adaptability and environmental performance.

What specific technological and digital innovations is BUSS ChemTech prioritising to further enhance pyrolysis recycling of mixed plastics? In your view, how will these developments create sustainable value across the advanced recycling sector?

Thomas Blocher: Our technology has already shown that it can provide off-taker ready oil without post-process for some feedstocks. We have just embarked on a long-term project which, if successful, will result in our technology achieving naphtha drop-in quality for the same feedstocks, and perhaps more importantly, the same oil quality with feedstocks of lower quality. Only then will we realize our target of successfully handling the type of waste present in most regions of the world, and not just the “clean” waste produced in much of western Europe. A secondary project will piggyback off of the work being done to develop inline analytical techniques that would then tie directly into the pyrolysis plant process control system to adjust the reactor parameters according to the incoming feedstock. Both projects are ambitious, but we are moving ahead eagerly and with optimism!

Source

nova-Institute, original text, 2025-11-06.

Supplier

BUSS ChemTech AG

nova-Institut GmbH

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals