Recycling is rapidly going digital. Artificial intelligence, sensor‑based insights, and virtual process twins are turning what used to be industrial guesswork into data‑driven precision. From sorting lines that learn on the go to value chains visible in real time, technology is redefining how circular systems perform.

AI‑powered and digital recycling will be among the key focus topics at this year’s Advanced Recycling Conference, taking place on 19–20 November 2025 in Cologne, Germany, and online. Explore novel digital and AI-based recycling innovations and meet the experts shaping the digital future of recycling.

Register now at www.advanced‑recycling‑conference.com.

In the following interview, Dmitri Didenko from Weatherford shares how intelligent automation and analytics are already reshaping industrial recycling operations.

© Weatherford

1. Innovation and Sustainability

While Weatherford has recently advanced digital solutions especially in the energy sector, for example through intelligent completions and electronic inflow control valves (e‑ICVs), digital transformation is reshaping all industries by enabling smarter, more efficient, and sustainable operations. Weatherford’s innovations range from electronic inflow control valves (e‑ICVs) to comprehensive data models, that integrate operational and financial metrics and demonstrate how combining real-time data with automation can reduce energy consumption and greenhouse gas (GHG) emissions.

What are the key opportunities you see for digitalisation to drive measurable sustainability gains in advanced recycling? How can integrated data-driven approaches help recycling stakeholders improve environmental outcomes while maintaining operational viability?

Digitalization is no longer just a “nice-to-have” but is essential in complex fields like advanced recycling, enhancing both efficiency and sustainability. At Weatherford, we have seen real-time data and automation reduce energy use and emissions in oil and gas, and we are confident these tools can deliver similar benefits in recycling.

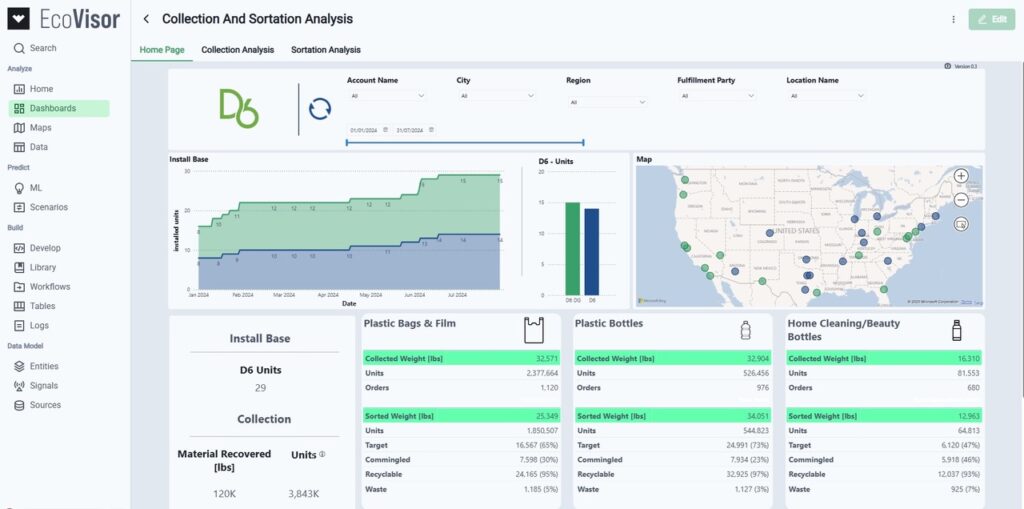

Our EcoVisor platform, originally developed to track emissions and energy at oil and gas sites, can be adapted to provide recycling facilities with real-time visibility into their environmental impact. Combined with our Unified Data Model (UDM), which integrates operational and financial data, it delivers a comprehensive view to support informed business decisions.

With this data-driven approach, recyclers can demonstrate the impact of their sustainability efforts and identify opportunities to reduce energy consumption and lower costs. It helps link environmental goals to real business outcomes.

2. Sustainability Gains Through Breakthrough Technology

Centralised digital platforms that unify data sources, such as SQL databases (Structured Query Language), spreadsheets like Smartsheets, and live sensor inputs, are significantly improving performance monitoring and decision-making. Techniques like Extract, Transform, Load (ETL) ensure data accuracy and completeness, while advanced statistical algorithms estimate missing or untagged waste metrics. Your company has highlighted the role of downhole insights and data-driven analytics to maximise system efficiency in energy production. Recycling processes face a comparable challenge with variable and unpredictable feedstocks (e.g., mixed and contaminated plastic waste) that impact yields and product stability.

Which digital breakthroughs offer the most immediate and scalable benefits for improving sustainability in recycling operations? Could you illustrate how predictive analytics, real-time dashboards, or weight allocation algorithms enhance transparency and decision-making across diverse recycling contexts, e.g., help operators stabilise and optimise recycling processes facing highly inconsistent input streams?

One of the greatest opportunities in recycling today is using digital tools to streamline data management and clarify complex processes. However, a major challenge is managing the vast amount of data collected. Sensor outputs, production logs, and financials often exist in separate systems, making it hard to connect and use for quicker, better decisions.

Predictive analytics has delivered gains, especially in planning and scheduling. Instead of reacting, operators address issues proactively. They can forecast downtime, predict when systems need maintenance, and model how process changes affect outcomes.

Our UDM consolidates disparate data sources into a single framework. It draws from spreadsheets, databases, and live equipment data, then utilizes analytics to transform raw data into actionable insights.

These digital tools not only improve sustainability but also simplify facility operations. They are scalable because they provide operators, managers, and executives with the visibility needed to make informed decisions that reduce waste, conserve energy, and improve efficiency.

3. Challenges & Opportunities

Despite their potential, digital and AI systems present integration challenges, especially when they depend on data from heterogeneous and sometimes incomplete sources. The scalability of these solutions also depends on aligning operational workflows with technology. However, access to unified, accurate, and real-time financial and performance data can empower operators to optimise scheduling, reduce costs, and forecast more effectively.

What are the primary hurdles operators face in implementing extensive digitalisation in advanced recycling? Conversely, how can overcoming these challenges through well-structured data integration and analytics create new opportunities for operational and financial improvements sector-wide?

In the process of digitalising recycling, one of the primary challenges is the fragmentation of existing systems. Many plants still rely on separate Excel spreadsheets, old databases, or even manual logs, making data integration challenging.

We addressed this fragmentation by developing the UDM. It creates a common data language without a complete system overhaul. This makes it easier to layer on analytics and forecasting tools on top.

In addition to data fragmentation, limited digital skills and tight IT budgets add to the challenge. Automation helps here. For example, EcoVisor processes data in the background, notifying personnel only if action is needed.

Ultimately, by overcoming these barriers, organizations can achieve significant benefits, including real-time cost tracking, reduced downtime, smarter scheduling, and overall leaner, greener operations.

4. Collaboration & Industry Dynamics

Successful digital transformation requires coordinated efforts among technology providers, recyclers, waste handlers, and investors. Weatherford’s history of cross-functional partnerships highlights the crucial role of blending expertise in data engineering, process optimisation, and finance to realise integrated digital platforms.

How do you foster collaboration across these sectors to build integrated, scalable digital solutions in recycling? What types of industry alliances or cross-sector exchanges are most effective for driving the validation and adoption of digital systems in the industry?

Digital transformation does not happen alone. At Weatherford, we have learned that building ecosystems by bringing together data experts, engineers, operators, and regulators is key. This approach is also being applied in our recycling initiatives.

A notable example is our customer D6 Inc., which, through its partnership with Walmart, integrates recycled content into packaging for Walmart shelves. This creates a closed supply chain that is both economically and environmentally sustainable. Such collaborations between recyclers and major retailers accelerate adoption and engage end users to participate.

We apply the same ecosystem-building approach in recycling by partnering with retailers, recyclers, waste handlers, and technology companies. Our open and flexible UDM acts as a centralized data platform, encouraging other vendors and partners to plug in and collaborate. To support these efforts, our EcoVisor platform offers transparent and reliable reporting for investors, regulators, and operators.

5. Future Innovations

The future of advanced recycling may lie in “smart factories” leveraging artificial intelligence (AI)-enabled predictive maintenance, dynamic inventory management, and automated scheduling based on material flows. Innovations such as expanded Internet of Things (IoT) networks, advanced analytics for missing data estimation, and real-time operational tracking promise to transform recycling plants into adaptive, efficient, and transparent enterprises.

Looking ahead, what are the key innovations that will define digitally optimised recycling facilities? How will these advances translate into sustainability, efficiency and economic benefits not only for operators but for broader recycling value chains, including investors, regulators, and consumers?

Smart, adaptive recycling facilities, powered by AI, are revolutionizing the industry. By predicting maintenance needs, managing inventory, and scheduling tasks, digitalization optimizes material flow and drives more effective recycling operations.

We are already utilizing AI-driven maintenance prediction in oilfields, identifying problems early to prevent downtime. Recycling lines are next. IoT sensors with edge computing will further enhance these facilities by bringing decision-making directly to the factory floor, reducing delays and improving responsiveness.

By incorporating UDM features that address missing data and detect anomalies, plants can implement monitoring systems that enhance efficiency, transparency, and resilience. These improvements benefit operators, investors, regulators, and consumers by supporting cleaner and more reliable recycling systems.In summary, digitalization extends beyond operational improvements and is a critical step toward achieving a circular economy. Weatherford remains committed to advancing this progress.

Source

nova-Institute, original text, 2025-10-30.

Supplier

nova-Institut GmbH

Weatherford International

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals