Today, scarce metals and unsustainable materials are used to build conductive circuits in electronic devices. To help reduce the dependency on these finite resources, the REFORM project aims to develop metal-free electronic components from bio-derived adhesives, conductive inks and flexible substrates. AIMPLAS participates in this EU funded project, led by CIDETEC, that focuses on the development of printed green electronics that will accelerate and guide the creation of a new European functional electronics supply chain.

Although each electronic device we own contains very limited amounts of critical materials, they are produced on a vast scale, meaning that the cumulative environmental impact of e-waste is substantial, particularly if components are embedded in ways that make recycling extremely difficult or uneconomic. Those devices that aren’t recycled or disposed of correctly can often be found in landfill sites, where all sorts of dangerous toxins and carcinogenic substances, such as mercury, lead and cadmium, leach into the surrounding soil.

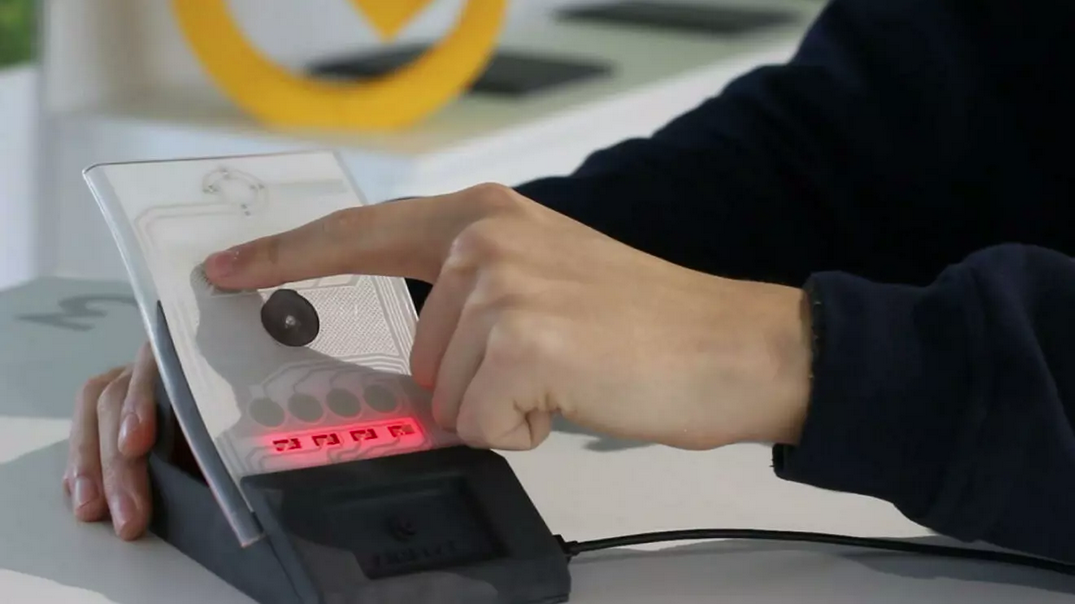

The REFORM project seeks to develop environmentally sustainable printed electronics by harnessing organic conductive inks and biodegradable or recyclable materials. Specifically, the project will develop three prototypes; a green smart logistics tag, a green embedded wireless sensor and a micro supercapacitor.

REFORM will employ eco-design principles to produce green printable electronics that meet the demands of multiple industries and sectors so that e-waste ceases to be a problem in the future. To achieve this goal, the project brings together world-leading academics, non-profit research organisations, industry experts and innovative businesses from across eight different European countries.

AIMPLAS will contribute its experience in the recyclability of the materials and products developed in the project. More concretely, AIMPLAS will develop a pathway to achieve an effective sorting of printed electronics, and a new innovative method for the recovery of metals that contain these products. After the sorting and metal recovery, AIMPLAS will test which recycling method is better for the printed electronics recycling, including chemical and mechanical recycling tests.

REFORM is a 42-month project and has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No 101070255.

Source

AIMPLAS, press release, 2023-08-02.

Supplier

AIMPLAS (Asociación de Investigación de Materiales Plásticos y Conexas)

CIDETEC

European Union

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals