For our AI Circular Economy Conference, we are delighted to have the opportunity to speak with two distinguished research experts: Rosario Othen and Florian Pohlmeyer from the Institute of Textile Technology (ITA) at RWTH Aachen University. In this insightful interview, they share their perspectives on how digital twins, data spaces and AI are not only driving technological innovation but also serving as strategic enablers of sustainable transformation in the process industry. We sincerely thank our speaker partners for this inspiring conversation and their valuable insights into how data ecosystems can accelerate the shift towards a circular and climate-neutral industry.

Join the dialogue on how AI and data are shaping the circular economy of tomorrow.

Register to join the conversation: https://ai-circulareconomy.eu/registration/

Become a sponsor: https://ai-circulareconomy.eu/sponsoring/

Exhibit on-site: https://ai-circulareconomy.eu/exhibition-booking/

1. Breaking Down Data Silos

Your research addresses fragmented data landscapes and missing interoperability as core barriers to decarbonising energy-intensive industries. From your perspective, what structural or organisational changes are needed to move from isolated data silos towards truly integrated, system-wide decision-making?

From our perspective, the key shift required is moving from project- and organisation-centric data management towards ecosystem-oriented governance models. This includes three structural changes:

- A clear data ownership, stewardship roles and incentives that make data sharing economically and strategically attractive across organisational boundaries.

- The adoption of interoperable standards and reference architectures that allow data, digital twins and AI models to interact seamlessly across the value chain rather than remaining locked in proprietary systems.

- Decision-making structures must evolve from isolated optimisation at asset or plant level towards system-wide optimisation, supported by shared data spaces and federated analytics.

In addition, this transformation requires a mindset and change-management shift. Employees must be supported in thinking and acting beyond departmental boundaries, with digital leadership explicitly reinforcing that data generated in one silo is a shared asset for the wider organisation and ecosystem. Only by aligning organisational responsibilities, technical standards and strategic incentives can fragmented data silos be transformed into integrated decision-support systems that enable effective decarbonisation in energy-intensive industries.

2. The Power of Modular Digital Architectures

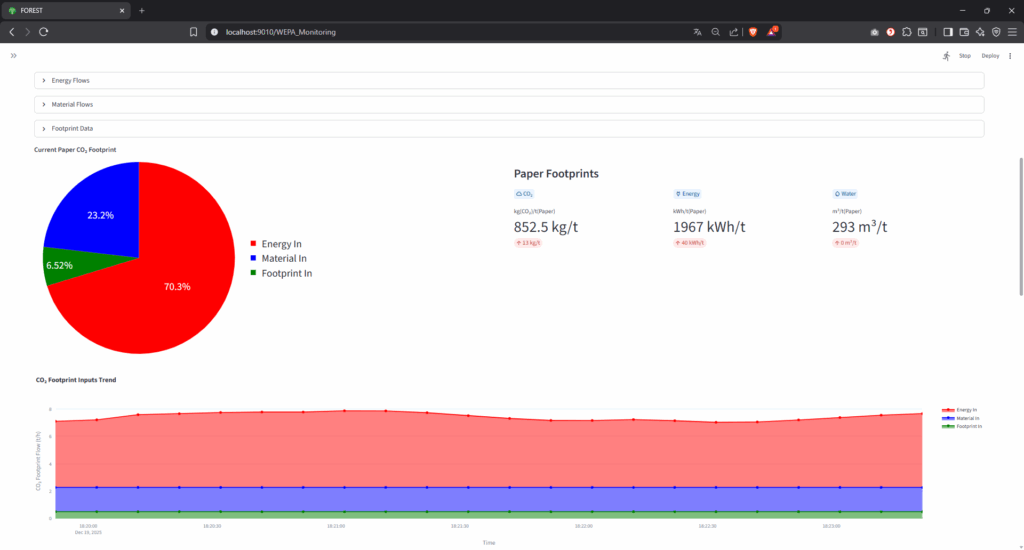

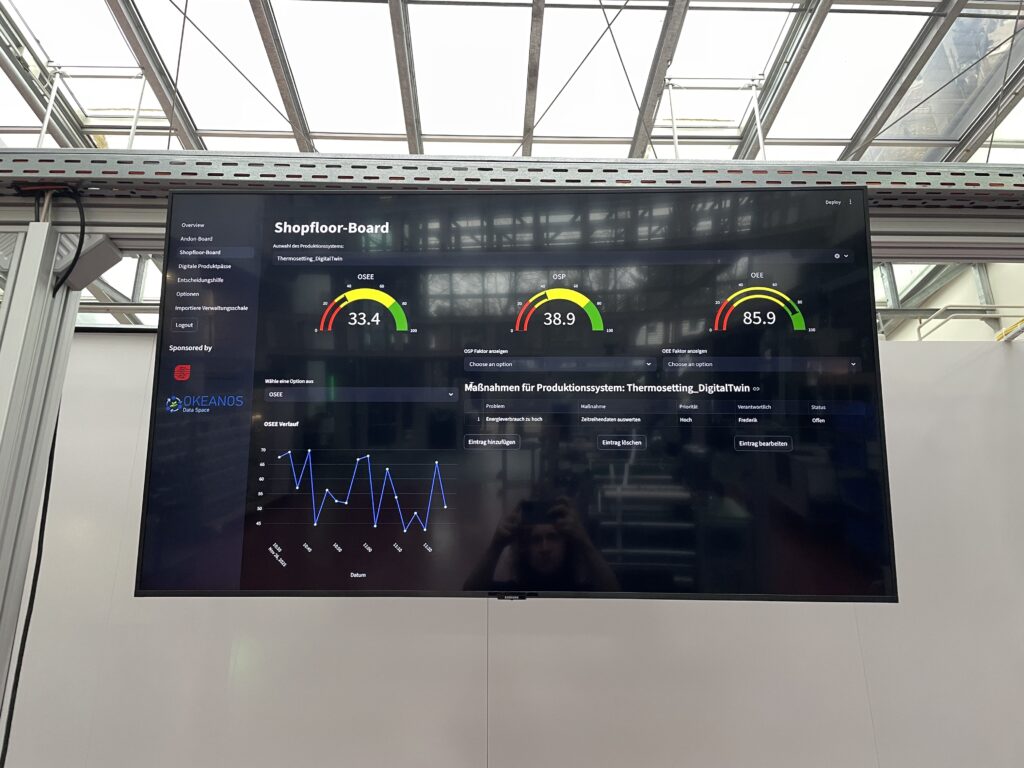

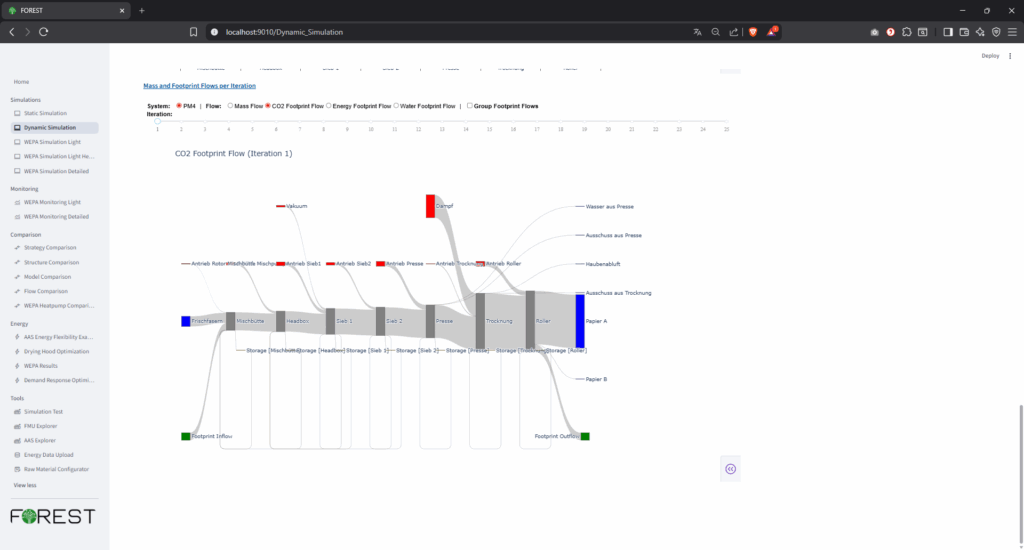

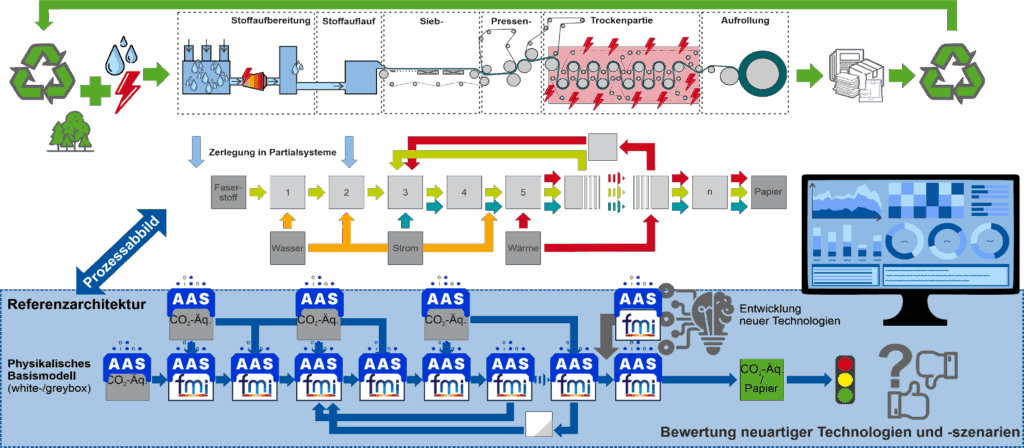

The FOREST project proposes a modular reference architecture combining digital twins, Asset Administration Shells and Functional Mock-up Units. Could you elaborate on how this modularity accelerates industrial transformation, and what kinds of insights companies can gain once such an architecture is established?

The key advantage of modularity is that it reduces site-specific engineering effort and makes scaling realistic. In FOREST, the Asset Administration Shell (AAS) provides the semantic backbone, and so-called Functional Mock-Up Units (FMUs) encapsulate simulation models from different engineering platforms. That means you can plug together assets, sections, utilities and external signals with well-defined interfaces instead of rebuilding everything for each mill or line.

3. Data Spaces as Enablers of Cross-Industry Transparency

With OKEANOS, you expand beyond the factory level and introduce a cross-company data space based on harmonised structures and Digital Product Passports. How might this type of shared digital infrastructure reshape collaboration, transparency and sustainability across entire value chains?

A shared digital infrastructure like OKEANOS enables a shift from bilateral data exchange to value-chain-wide collaboration. By using harmonised data structures and Digital Product Passports, actors can access consistent, trusted information across company boundaries. This increases transparency on materials, processes and environmental impacts, reduces coordination effort, and enables joint optimisation instead of isolated improvements. Ultimately, such data spaces create the foundation for scalable sustainability strategies, circular business models and evidence-based decision-making across entire value chains.

4. AI as a Driver of Proactive Industrial Planning

AI plays a key role in forecasting, optimisation and lifecycle assessment within your framework. What types of AI-driven analyses do you consider most impactful for enabling proactive, rather than reactive, industrial planning — especially in sectors with high energy demand and complex supply chains?

The most impactful AI-driven analyses are those that combine predictive and prescriptive capabilities across the lifecycle. This includes demand and energy load forecasting to anticipate capacity constraints and emission peaks, process-level optimisation to identify efficiency potentials before deviations occur, and AI-supported lifecycle assessment that dynamically evaluates environmental impacts based on real operational data. In complex supply chains, scenario-based simulations and digital-twin-enabled optimisation are particularly powerful because they allow companies to test decarbonisation strategies virtually and act proactively rather than responding to disruptions or regulatory pressure after the fact. A further critical capability is model lifecycle and drift management: in real plants, boundary conditions change, including equipment, recipes, tariffs and suppliers, so AI methods must monitor drift, retrain surrogates responsibly, and keep assumptions transparent to maintain long-term trust.

Across all these use cases, the most important requirement is traceability: stakeholders must be able to understand how the AI arrived at a recommendation, which assumptions and data sources were used, why certain trade-offs were prioritised, and what evidence supports the proposed action. The common thread is proactive decision support: AI that anticipates, quantifies trade-offs, and recommends actions in a governed, auditable way. The winning AI use cases are the ones that convert uncertainty into operational choices while remaining explainable and accountable.

5. A Digital Ecosystem for the Next Decade

Your abstract emphasises that the approach is adaptable across sectors and organisational boundaries. Looking ahead, how do you envision digital ecosystems evolving in the next decade, and what will determine whether companies succeed in using data and AI as true enablers of sustainable industrial transformation?

In the next decade, digital ecosystems in energy-intensive industries will shift from fragmented point solutions to integrated operating models: connected factories where automation, electrification and digital services enable proactive optimisation, supported by real-time transparency, AI analytics and lifecycle services.

Success will hinge on a few fundamentals: cybersecurity as a prerequisite for IT/OT convergence in brownfield plants, traceability so decisions and assumptions are explainable and auditable, and measurable business value tied to productivity, availability and CO₂ KPIs. Scaling will require robust, modular reference architectures and data-space collaboration with clear standards and rules that protect know-how. Companies must build a learning organisation with interdisciplinary teams and supported change capability, so digital tools translate into sustained operational performance.

Source

nova-Institute, original text, 2026-01-13.

Supplier

European Commission

European Union

Institut für Textiltechnik (ITA) – RWTH Aachen

nova-Institut GmbH

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals