The SAGROPIA project recently hit a major milestone in turning innovative biopesticide research into something real and scalable for European farmers. Behind the scenes, a passionate team from Rovensa Next tackled the nitty-gritty challenge that every successful biotechnology faces: moving from small laboratory batches to large-scale, industrial production while preserving the quality, performance, and environmental promise of each product.

So, how does this scaling-up process actually work, and why does it matter for our fields, food, and environment? Let’s pull back the curtain.

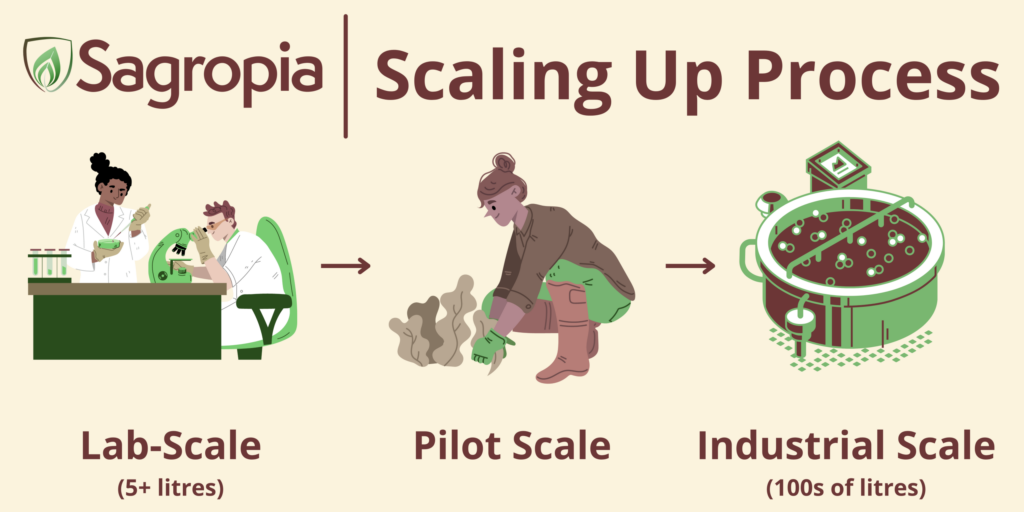

At its heart, upscaling is all about taking great research and making it practical and applicable in the real world, at scale. For example, microorganisms and plant extracts will behave very differently when their “home” changes from a tiny beaker to a tank the size of a wardrobe. Every step, from growing cells to cleaning up the final mixture, needs to be re-thought, tweaked, and tested when upscaling.

Take the SAGROPIA nematicide ‘OR-501’ (a bio-based pesticide targeting plant-parasitic roundworms) as an example. It’s based on living microorganisms that need just the right conditions to thrive. First, the team gave these microbes the perfect meal and living conditions in small tanks (5L and 50L bioreactors), then moved them to larger vessels, working up to semi-industrial scale. They discovered that not all water is created equal – pure distilled water gave much better results. Thanks to careful adjustments and repeated testing, they managed to concentrate these beneficial cells and harvest them efficiently, making a product strong enough to use in the field at farm-scale.

Not all the formulas tested under SAGROPIA rely on microbes, though. The formulation ‘C-009’, for example, comes from marigold extract and needed its own distinct scale-up journey. Producing hundreds of litres at a time, the team had to prevent the valuable ingredients from breaking down – no easy feat! Trial batches on pilot equipment confirmed that what worked in the lab was now working at “factory” scale, too.

Sometimes, it’s about more than just size. With plant protection product, AXPERA for example, cost was a key issue. By experimenting with the “food” fed to the amoeba used to produce the active substance, the scientists cut out unnecessary nutrients and found a way to sterilize everything with a short blast of heat, slashing manufacturing costs by 90%. Even at half-ton volumes, the results matched the lab’s best, and the product kept its pest-fighting power at scale.

Why does all this matter? Scalable, sustainable production of biopesticides is the bridge between discovery and real-world impact. Without these breakthroughs, next-generation crop protection would stay trapped in the lab. Thanks to the SAGROPIA team’s work, these eco-friendly alternatives are one step closer to replacing traditional chemical pesticides across Europe. That means cleaner soils, healthier water, safer food, and a boost for biodiversity without asking farmers to sacrifice results.

The timing of these advances in production could not be better, as earlier this year SAGROPIA launched a major network of field trials across five different countries. These trials – spanning The Netherlands, France, Germany, Poland, and Switzerland – are putting the newly upscaled biopesticide formulations into practice on real farms and under a variety of climatic conditions. With about 30 individual experiments set to run over three years, the field trials compare standard local farming practices with alternative strategies built around SAGROPIA’s integrated pest management approach. Each trial systematically assesses not only how the new biopesticide-based solutions perform against key pests and diseases in potato and sugar beet, but also the broader effects on crop yields, quality, and non-target organisms. The successful scale-up and formulation protocols developed in the project are now a crucial foundation for these trials, enabling researchers and farmers alike to evaluate whether these nature-inspired solutions can genuinely reduce reliance on chemical pesticides.

The journey from SAGROPIA’s laboratory to Europe’s farm is far from simple, but bit by bit, obstacles are being cleared. With each success in upscaling, new nature-based solutions for pest and disease control are getting closer to becoming a routine part of sustainable agriculture across the continent. As more fields benefit from these advances, the future of European farming looks a little greener – and a lot more resilient and sustainable.

Author

Tristan Bath

Source

SAGROPIA blog, press release, 2025-08-06.

Supplier

amoéba-nature

Rovensa

RTDS Group

SAGROPIA

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals