- Bio-based EA has a certified 14C-traceable content of 40% and offers a Product Carbon Footprint Reduction of 30% compared to fossil-based EA

- Readily available drop-in solution for a broad range of applications

- Starting Q4 2024, BASF plans to exclusively offer bio-based Ethyl Acrylate going forward

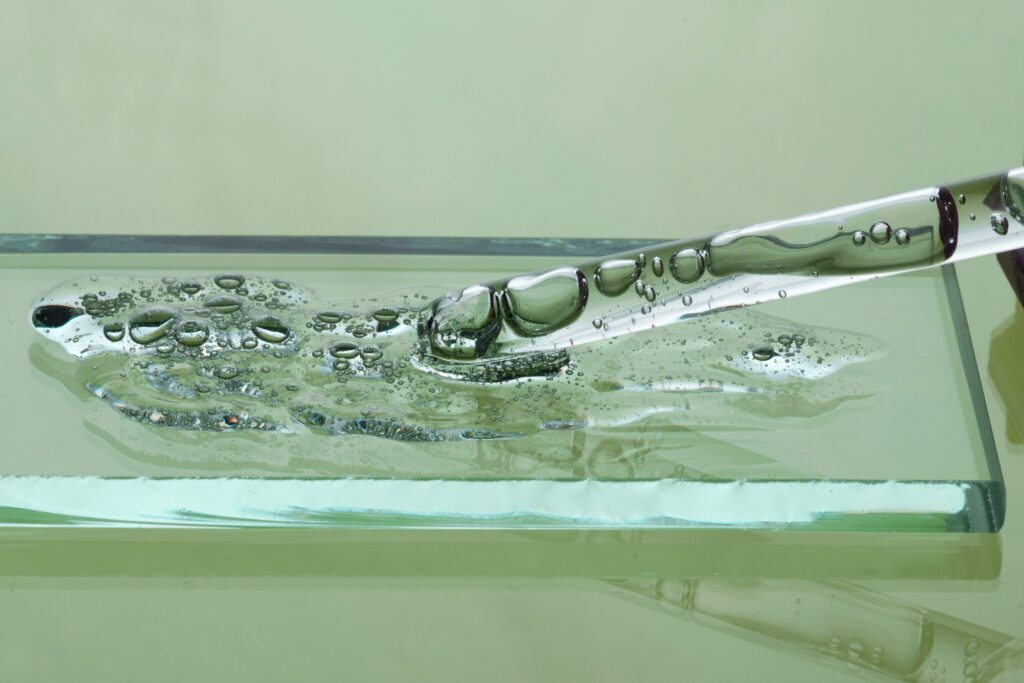

BASF gives a clear sign towards biotransformation of their (Meth)Acrylate portfolio and switches their production to bio-based Ethyl Acrylate (EA) starting Q4 2024. With a 14C-traceable bio content of 40% according to DIN EN 16640 and a low Product Carbon Footprint (PCF1), bio-based EA from BASF helps customers worldwide to reach their sustainability goals. The product offers a PCF reduction of ~30% compared to fossil-based EA. Additionally to regular bio-based EA, BASF also offers bio-based Ethyl Acrylate BMB ISCC Plus. Here, the remaining carbon content originated from fossil based acrylic acid is ISCC PLUS certified, and by applying BASF’s biomass balance (BMB2) approach, this variant offers a further reduced product carbon footprint.

BASF’s bio-based Ethyl Acrylate uses sustainable bioethanol predominantly from European sources with grain as a feedstock. BASF applies strict sustainability criteria for the material use of biomass. The bioethanol purchased by BASF does not compete with food production: Bioethanol is mainly produced from residues of starch production, lower quality grains or molasses, all of which are not used in food production. Grains that are neither suitable for use as food nor feed can also be used for bioethanol production.

Das biobasierte Ethylacrylat der BASF setzt überwiegend nachhaltiges Bioethanol aus europäischen Quellen mit Getreide als Rohstoff ein. BASF setzt strenge Nachhaltigkeitskriterien für die stoffliche Nutzung von Biomasse an. Das von BASF gekaufte Bioethanol steht in keiner Konkurrenz zur Lebensmittelproduktion: Bioethanol wird hauptsächlich aus Reststoffen der Stärkeproduktion, minderwertigem Getreide oder Melasse hergestellt, die allesamt nicht in der Lebensmittelproduktion verwendet werden können. Getreide, das weder als Lebens- noch als Futtermittel geeignet ist, kann ebenfalls für die Bioethanolproduktion eingesetzt werden.

Bio-based EA offers a broad application range and can be used in a wide variety of polymer dispersion applications, with the Coatings and Adhesives industries as the primary target industries.

BASF’s bio-based Ethyl Acrylate is ‘OK biobased’3 certified by TÜV Austria since March 2024.

1 BASF’s product carbon footprint (PCF) calculations for conventional products follow the requirements and guidance given by ISO 14067:2018. A TÜV Rheinland methodology review has certified that the SCOTT PCF methodology developed and used by BASF SE is based on scientific evidence, meets ISO 14067:2018 and the Together for Sustainability PCF policy, and reflects the state of the art (ID no. 0000080389: BASF SE – Certipedia). TÜV Rheinland also confirms that the biomass balance (BMB) PCF calculation method and the associated PCF reduction for BMB-certified products follow the conventional LCA method in accordance with ISO 14067 and the Together for Sustainability (TfS) policy.

2 Find out more about BASF’s biomass balance approach at: https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/circular-economy/mass-balance-approach/biomass-balance.html

3Find out more about the ‘OK biobased’ certification here: https://en.tuv.at/ok-biobased-en/

Source

BASF, press release, 2024-08-08.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals