A low-cost, tin-based catalyst can selectively convert carbon dioxide to three widely produced chemicals — ethanol, acetic acid. Lurking within the emissions from many industrial operations is an untapped resource — carbon dioxide (CO2). A contributor of greenhouse gas and global warming, it could instead be captured and converted to value-added chemicals.

In a collaborative project involving the U.S. Department of Energy’s (DOE) Argonne National Laboratory, Northern Illinois University and Valparaiso University, scientists report a family of catalysts that efficiently converts CO2 into ethanol, acetic acid or formic acid. These liquid hydrocarbons are among the most produced chemicals in the U.S. and are found in many commercial products. For example, ethanol is a key ingredient in numerous household products and an additive to nearly all U.S. gasoline.

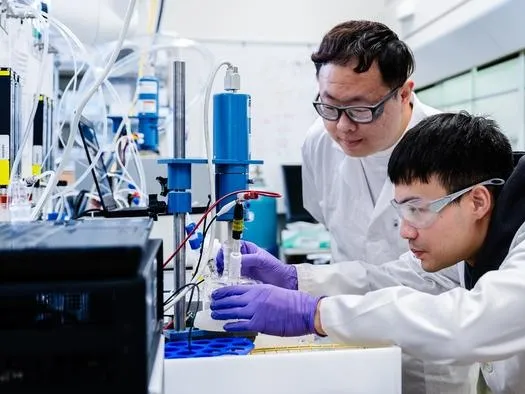

The catalysts are based on tin metal deposited over a carbon support. “If fully developed, our catalysts could convert the CO2 produced at various industrial sources to valuable chemicals,” said Di-Jia Liu. “These sources include fossil fuel power plants and bio-fermentation and waste treatment facilities.” Liu is a senior chemist at Argonne and a senior scientist in the Pritzker School of Molecular Engineering at the University of Chicago. “Our finding of a changing reaction path by the catalyst size is unprecedented.” — Di-Jia Liu, senior chemist

The method used by the team is called electrocatalytic conversion, meaning that CO2 conversion over a catalyst is driven by electricity. By varying the size of tin used from single atoms to ultrasmall clusters and also to larger nano-crystallites, the team could control the CO2 conversion to acetic acid, ethanol and formic acid, respectively. Selectivity for each of these chemicals was 90% or higher. “Our finding of a changing reaction path by the catalyst size is unprecedented,” Liu said.

Computational and experimental studies revealed several insights into the reaction mechanisms forming the three hydrocarbons. One important insight was that the reaction path completely changes when the ordinary water used in the conversion is switched to deuterated water (deuterium is an isotope of hydrogen). This phenomenon is known as the kinetic isotope effect. It has never been previously observed in CO2 conversion.

This research benefited from two DOE Office of Science user facilities at Argonne — the Advanced Photon Source (APS) and Center for Nanoscale Materials (CNM).

“Using the hard X-ray beams available at the APS, we captured the chemical and electronic structures of the tin-based catalysts with different tin loadings,” said Chengjun Sun, an Argonne physicist.

In addition, the high spatial resolution possible with a transmission electron microscope at CNM directly imaged the arrangement of tin atoms, from single atoms to small clusters, with the different catalyst loadings.

According to Liu, “Our ultimate goal is to use locally generated electricity from wind and solar to produce desired chemicals for local consumption.”

This would require integrating the newly discovered catalysts into a low-temperature electrolyzer to carry out the CO2 conversion with electricity supplied by renewable energy. Low-temperature electrolyzers can operate at near ambient temperature and pressure. This allows rapid start and stop to accommodate the intermittent supply of renewable energy. It is an ideal technology to serve this purpose.

“If we can selectively produce only the chemicals in need near the site, we can help to cut down on CO2 transport and storage costs,” Liu noted. “It would truly be a win-win situation for local adopters of our technology.”

The corresponding scientific paper appeared in the Journal of the American Chemical Society. In addition to Di-Jia Liu and Chengjun Sun, authors include Haiping Xu, Jianxin Wang, Haiying He, Inhui Hwang, Yuzi Liu, Haozhe Zhang, Tao Li, John V. Muntean and Tao Xu.

Support for the research came from DOE’s Office of Energy Efficiency and Renewable Energy under the Advanced Manufacturing Office, Industrial Efficiency & Decarbonization Office. Additional support was provided by Argonne’s Laboratory Directed Research and Development fund.

Source

Argonne National Laboratory, press release, 2024-05-21.

Supplier

Advanced Manufacturing Office (AMO)

Advanced Photon Source (APS)

American Chemical Society (ACS)

Argonne National Laboratory

Center for Nanoscale Materials

Center for Nanoscale Materials (CNM)

Industrial Efficiency & Decarbonization Office

Laboratory Directed Research and Development (LDRD)

Northern Illinois University

Office of Energy Efficiency & Renewable Energy

University of Chicago

Valparaiso University

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals