- New research group launched

- Progress in extracting chemicals from plants

- Further stimulus for the circular economy

Covestro is expanding its competencies in industrial biotechnology. The plastics manufacturer intends to make increasing use of microorganisms and enzymes to make its products and processes even more sustainable. In particular, new recycling processes based on biotechnology are also to be developed. To this end, the biotechnology competence center, which has been in operation for four years, has now been expanded to include a publicly funded research group. At the same time, Covestro is making progress in its efforts to produce the important chemical aniline entirely from plants for the first time with the help of microorganisms.

“Biotechnology has enormous potential to produce plastics in a more environmentally friendly and efficient way,” says Dr. Markus Steilemann, CEO of Covestro. “As an innovation-oriented company, we want to expand our capabilities in this area. In particular, we expect this to provide further stimulus for the circular economy, to which we are completely gearing our company.”

Recycling with enzymes

In order to better tap the potential of industrial (“white”) biotechnology for plastics production, the junior research group enzyme catalysis, or NEnzy for short, has now been established at Covestro. It will receive a total of 2.5 million Euros in funding from the German Federal Ministry of Education and Research for five years and is cooperating closely with RWTH Aachen University in Germany.

The new group is working to recycle end-of-life products and plastic waste through enzymatic recycling. The researchers also want to use enzymes to treat wastewater in plastics production. Another focus is the targeted and complete decomposition of used plastic in nature.

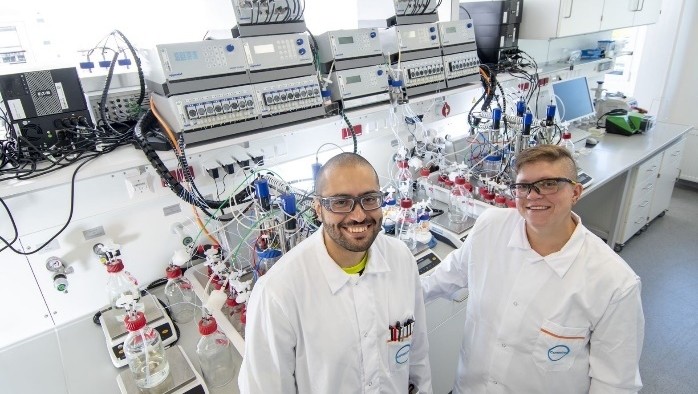

New laboratory

The experts now also have more space and even better equipment – in a new laboratory that Covestro has built at its headquarters in Leverkusen. Here, biotechnological processes can be represented in a particularly realistic way in a wide range of sizes, from one milliliter to soon 100 liters of reaction volume.

“We are taking nature as our model, which has created sensational processes and has practiced closed-loop recycling for millions of years,” says Dr. Gernot Jäger, who heads Covestro’s Biotechnology Competence Center. “With the help of enzymes and microorganisms, we can efficiently use alternative raw materials and thus replace fossil resources. At the same time, unwanted byproducts can be avoided or at least reduced significantly.”

Chemicals from plants

Specifically, Covestro is already using biotechnology to research and develop new ways to sustainably produce aniline. This basic chemical plays an important role in plastics production worldwide. Until now, it has been obtained almost exclusively from fossil raw materials such as petroleum, which releases CO2. Covestro needs aniline to produce a precursor (MDI) that is used to make insulating foam for buildings and refrigeration equipment.

Together with partners from industry and science, Covestro has developed a pioneering process to produce aniline from plant-based raw materials such as straw or sugar beet plants in an environmentally compatible way using microorganisms. Fully biobased aniline has already been obtained in this way and successfully processed into test products. Now the process, which has already won several awards, is to be further developed on a larger scale. The project is funded with public funds from the German Federal Ministry of Food and Agriculture.

Another precursor for coatings and adhesives (HMDA) can already be produced on a larger scale from plants and with the aid of biotechnology. Covestro and the U.S.-based biotech company Genomatica have succeeded in doing this through a partnership.

In biotechnology, there are several major areas that are identified by colors.

White or industrial biotechnology is used in industrial production processes, especially in the chemical industry.

Green biotechnology helps in agriculture, for example, to make plants more resistant to climate change.

Red biotechnology advances medicine – for example, to produce vaccines like those used to protect against Corona.

About Covestro

Covestro is one of the world’s leading manufacturers of high-quality plastics and their components. With its innovative products and processes, the company contributes to greater sustainability and quality of life in many areas. Covestro supplies customers around the globe in key industries such as mobility, construction and housing, and electrical and electronics. In addition, Covestro’s polymers are used in areas such as sports and leisure, cosmetics, healthcare and in the chemical industry itself.

The company strives to be fully circular and aims to become carbon neutral by 2035 (Scope 1 and 2). In the 2021 fiscal year , Covestro generated sales of €15.9 billion. As of the end of 2021, the company produced at 50 sites worldwide and employed around 17,900 people (converted to full-time positions).

Source

Covestro, press release, 2022-11-29.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals